Project Background

Shantou Ultrasonic Printed Circuit Board Company (hereinafter referred to as Ultrasonic) was founded in 1985. It is a Sino - foreign joint venture enterprise specializing in the production of double - sided, multi - layer printed circuit boards and high - density interconnect laminate boards. It is a vice - chairman unit of the China Electronic Circuit Industry Association (CPCA), and has won the titles of national high - tech enterprise and "one of the top 100 PCB enterprises in the world". Ultrasonic owns many international leading product technologies, including high - frequency and high - speed printed circuit boards, high - performance HDI printed circuit boards, high - performance single - piece vehicle - mounted capacitive screens, and high - contrast VA new - type displays. Its "mobile communication mobile phone printed circuit board industrialization" project has been listed as a "national high - tech industrialization demonstration project" by the National Development and Reform Commission and the Ministry of Industry and Information Technology.

The new factory area of Ultrasonic is positioned to specialize in the research and development and production of high - frequency and high - speed printed circuit boards and high - performance HDI printed circuit boards. The product process features are that the same product will be sent to the same type of equipment for multiple cycles of processing and lamination, with a complex process, very high line density and complexity, enabling high - speed signal transmission and reliability design. Therefore, the adaptability and integration requirements for the system are also very high.

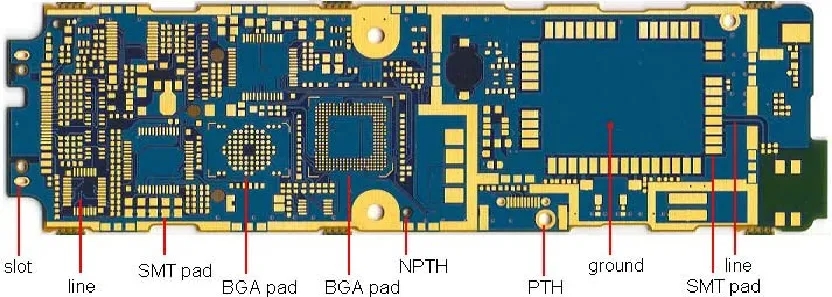

HDI Board

Ultrasonic applies advanced technologies, aiming to build a brand - new automated, digitized, and intelligent factory. It plans to implement APS scheduling, AGV logistics and loading and unloading, multiple production modes and seamless automatic switching of multi - product orders, and uses refined actual data to drive enterprise operation improvement and management upgrade. Shanghai Glorysoft Software Co., Ltd., relying on its years of accumulation in the pan - semiconductor industry and a full stack of product lines, has joined hands with Ultrasonic to build the first CIM platform in China's PCB industry that integrates IT and OT technologies.

Project Highlights

Large - scale, Complex, Multi - system Integrated CIM Application

The Ultrasonic CIM platform integrates more than ten systems, covering APS advanced scheduling system, MES production execution system, QMS quality management system, WMS warehouse management system, PMS equipment management system, EAP equipment collection and control system, etc., as well as integration with ERP and other systems. Through multi - system integration, an Ultrasonic digital factory is built, standardizing the Ultrasonic standardized management process and achieving comprehensive intelligent operation. At the same time, it meets the requirements of complex interaction and high production real - time of product technologies such as high - density interconnect technology HDI.

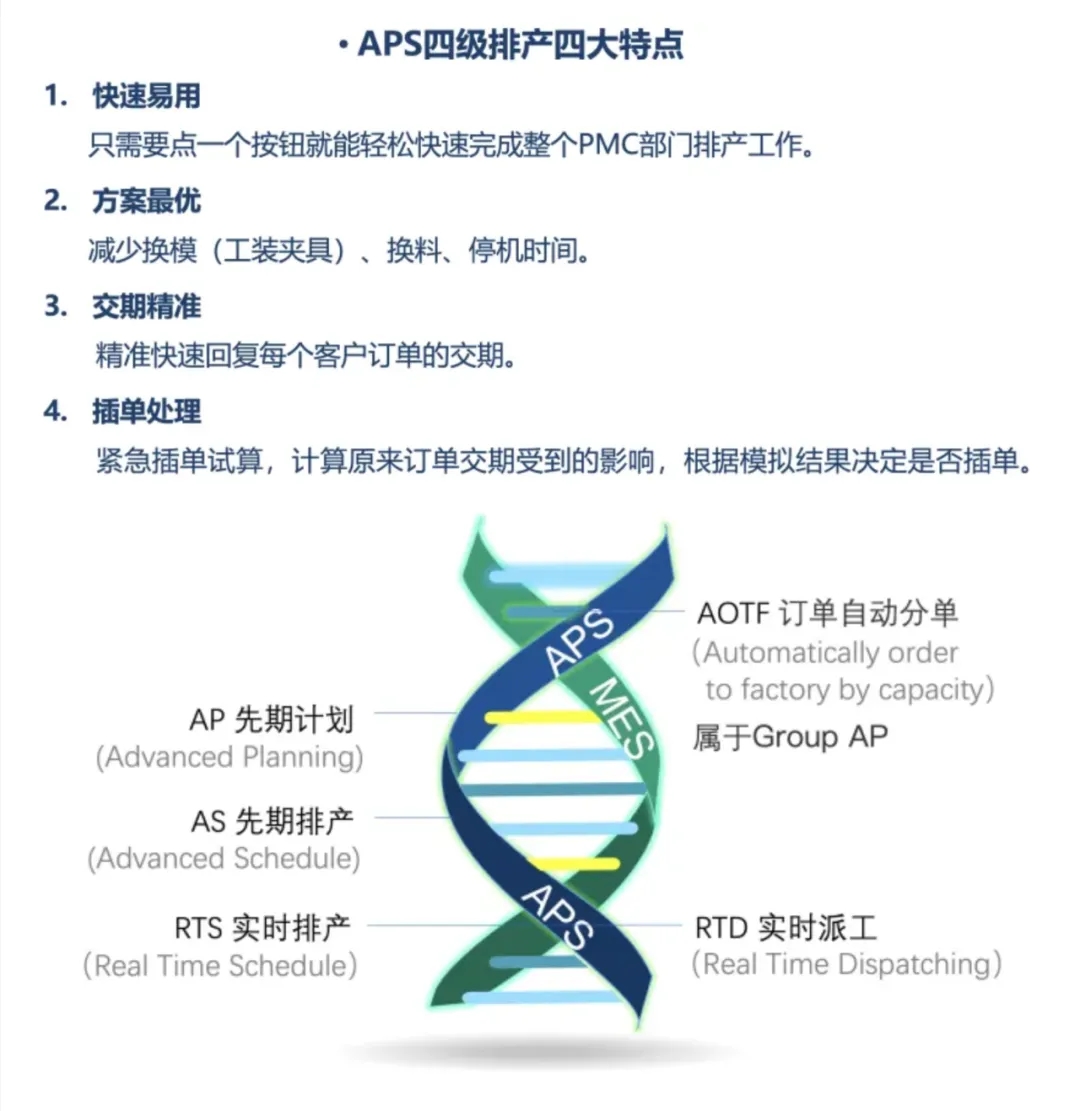

APS Production Equipment Coordination and Advanced Scheduling

The APS system is used for dynamic scheduling of on - site dispatching, logistics, and actual production. The Glorysoft APSwell© product starts from influencing scheduling factors, obtains product MI information through modeling, automatically calculates product scheduling parameters, sets various constraints and rules, automatically calculates the main plan to form a rhythmic dynamic main plan, and various production dynamic changes fed back by each system, thereby pulling the dynamic process production plan of real - time scheduling RTS, and relying on the EAP and logistics scheduling system for real - time dispatching, automatically making up for the difference in on - site automation. At the same time, the Glorysoft project team also refines and improves according to various analysis reports of the system, promoting the improvement of the process and the solidification of the lean culture. Although the design and integration work is complex and tedious, the technical personnel finally present a fast, convenient, and easy - to - use APS system to the user end, providing data support for the intelligent management level of the Ultrasonic management layer.

Logistics Automation with No Backlog Inventory between Processes

The project realizes the visualization of factors such as the production state of on - site equipment and the water level of the warehouse, making various handling tools seamlessly connect with the system, helping the factory increase the inventory turnover rate and reduce operating costs.

Production Anti - Error Control Automation

With the support of the complete product system of Glorysoft, through anti - error control of production process, time management, batch and lot number, and mapping data traceability, the production quality and efficiency are greatly improved.

Full Life Cycle Board Traceability

The amount of data processed by PCB industry board parts is very large, reaching hundreds of millions of levels, resulting in very slow data traceability. In response to this problem, the Glorysoft team uses advanced big data technology, combined with profound industry knowledge accumulation, to complete the traceability of the entire production cycle from material feeding and panel combination to shaping into SET and PCS, as well as comprehensive traceability of production conditions and other aspects during the board part production process. It systematically meets the traceability requirements of high standards, high quality, and full life cycle of products for the head customers of Ultrasonic in the electronics and automotive industries.

Project Significance

During the implementation of the Ultrasonic CIM project, Glorysoft organized an experienced implementation team, introduced the best practices of advanced manufacturing, delved into various technical details, actively sought solutions, successfully overcame the problem of complex system integration, and helped Ultrasonic build a milestone in the application of HDI technology in the PCB industry.

Glorysoft has served many leading enterprises in the PCB industry such as Shennan, Pengding, Shenlian, Visionox, Xinchuanyuan, Yidong Electronic, etc. In the future, it will continue to innovate, applying AI and big data and other frontier technologies, promoting the development of intelligent engineering design, intelligent quotation, process quality big data analysis, and overseas factory remote control and other fields, accelerating the digitalization and intelligence process of the PCB industry, helping more PCB enterprises jointly build world - class printed circuit board factories with strong comprehensive strength and international competitiveness.