Project, Taking the Lead in Successfully Realizing the Full Coverage of the Solar Energy Industry Chain In recent years, with the increasing demand for carbon neutrality, green energy represented by solar power generation has received more and more attention. Driven by the "Intelligent Manufacturing 2025" plan, solar power plants are gradually carrying out digital reforms to ensure the rapid completion of the digital production transformation of the solar energy industry.

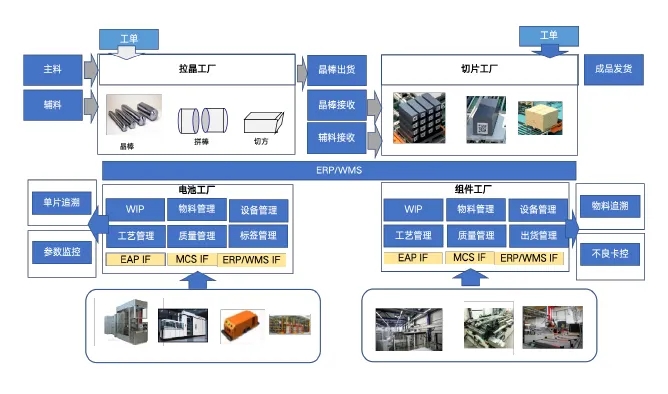

Based on years of experience in CIM (Computer Integrated Manufacturing) technology and implementation in the semiconductor industry, Glorysoft has taken the lead in successfully completing the CIM research and development in the entire solar energy industry chain, including the development and system implementation of CIM systems in fields such as crystal pulling and slicing, solar cell manufacturing, solar module, and solar bracket.

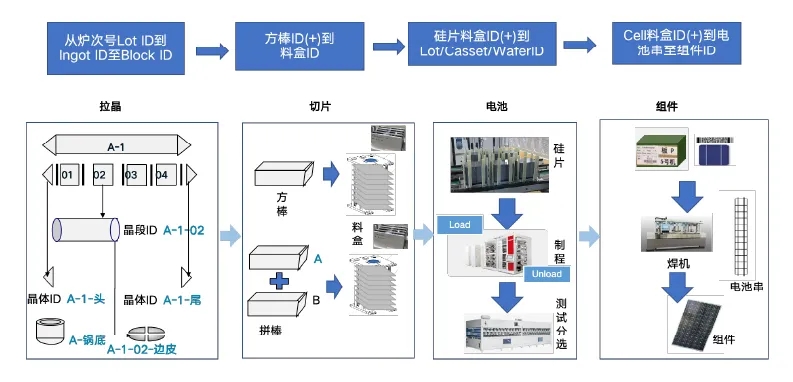

The Glorysoft CIM system has been applied to the entire process of solar energy production. It not only fully covers mainstream technologies such as HJT (Heterojunction with Intrinsic Thin - Layer, intrinsic thin - layer heterojunction), PERC (Passivated Emitter and Rear Contact, passivated emitter and rear contact), and Topcon (Tunnel Oxide Passivated Contact solar cell, tunnel oxide passivated contact solar cell technology) in the battery production process but also achieves a high precision of over 95% in single - wafer traceability, far ahead of the industry. Recently, Glorysoft signed a CIM project with the module factory of Tongwei Group Co., Ltd. This cooperation has filled the last technical gap in the domestic solar module field and presented the complete CIM landing application experience for the first time in the industry.

Multi - factory System Construction

Project Highlights

•The single - wafer traceability rate of solar energy ranks first in the industry, with a wafer - level traceability rate standard as high as 95%, far exceeding the industry standard of about 70%

• Human efficiency improvement (5GW battery): Equipment personnel reduced by 12.7%; Process personnel reduced by 21.6%; Production personnel reduced by 4.7%

• Equipment OEE increased by 6%, and the climbing stage time is saved by 2 - 3 months

In recent years, Glorysoft has successfully assisted many leading solar energy enterprises in smoothly completing their digital transformation, such as Hesheng Silicon Industry (Xinjiang Base), JA Solar (Yiwu Base, Yangzhou PERC and HJT), Canadian Solar (Funing Base), Tongwei Solar (Hefei HJT), Tongwei Solar (Jintang HJT), etc., winning unanimous praise from enterprises and accumulating rich industry experience. While actively investing in technological innovation and obtaining multiple patents, Glorysoft continuously launches new versions to avoid the repetition of technical documents, ensuring the diversity and novelty

Full traceability of product information

Full-stack solution - suitable for different business forms and adapted to the needs of enterprise information construction at all stages

Report Analysis - Production Reports