Glorysoft's independently developed LOFA (Light Off Factory Assistant) has been successfully applied in OM (Optical Microscope) equipment, marking a significant achievement in the field of 12-inch semiconductor manufacturing. LOFA focuses on automating all workflow processes in the FAB factory's OQA (Outgoing Quality Assurance) department through its highly automated solutions, filling in the most crucial piece of the puzzle for the entire FAB factory's unmanned process.

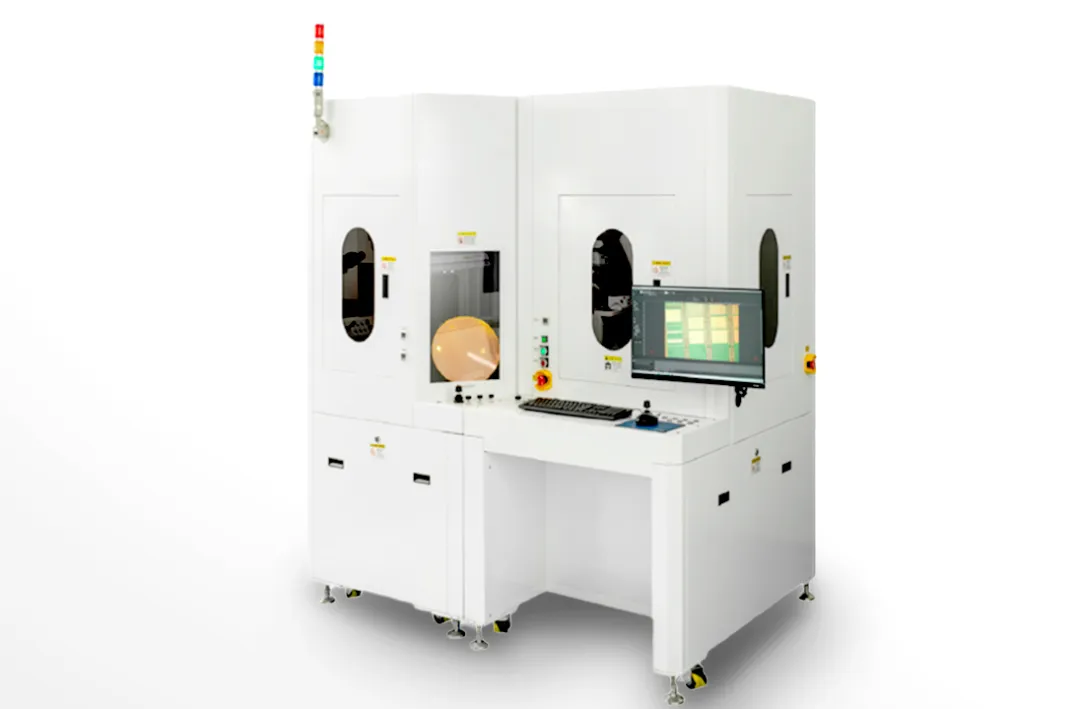

OM equipment plays a vital role in detecting defects in large-scale wafers. However, OM equipment poses a significant challenge for automation, requiring operators to manually adjust the wafer's position while closely monitoring the wafer's surface to identify and manually classify defects. Prolonged work can easily lead to decreased efficiency and missed detections. Additionally, the proficiency of operators directly affects the machine's WPH (wafers per hour), and machine idleness and personnel shortages during breaks or holidays further impact production capacity.

Illustration: Wafer Inspection OM Equipment

Many manufacturers have attempted to address these industry pain points but have all failed. The reason is that traditional pure software solutions cannot replace human eyes in collecting wafer information. It is challenging to cover the front, back, and edges of the wafer during the collection process. Furthermore, accurately classifying the collected defects requires substantial defect classification experience.

How Engineers Tackle These Difficulties:

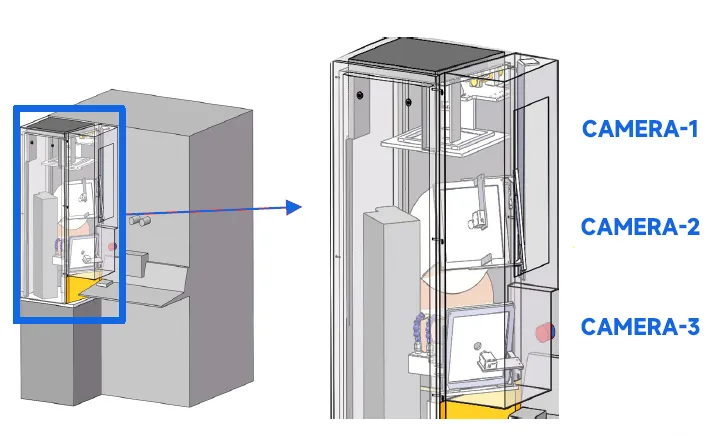

Replacing the Operator's Eyes: After extensive research and design, Glorysoft's R&D engineers developed customized hardware expansion solutions for different machines. Without invading the machine, high-precision light sources and cameras are installed in three different positions to detect wafers comprehensively.

Replacing the Operator's Actions: PLC control is added to the machine end to virtually replace physical operating tools such as knobs and joysticks. By connecting to LOFA-Bots, automatic focusing and wafer rotation can be achieved by LOFA-Bots.

Replacing the Operator's Brain: The LOFA-AI module utilizes advanced image recognition technology, deep learning, and accumulated defect classification experience in the semiconductor industry to automatically and accurately classify OM defects. The classification success rate can reach over 95%.

However, this was not enough. Glorysoft found that traditional FABs manually upload OM results to the DN (Defect Notice system), leading to inefficiencies and errors. Leveraging its platform integration advantages as a one-stop CIM supplier, Glorysoft streamlined the entire process, enabling auto DN upload, auto ink, and even auto-generation of shipment reports, successfully automating the entire OQA process.

Ultimately, LOFA achieves a perfect combination of software, hardware, and multi-system platforms in OM scenarios.

Specific Functions Implemented by LOFA Bots:

Automatic loading and unloading

Automatic recipe selection

Automatic macro inspection

Automatic air gun dust removal

Automatic micro inspection

Automatic defect classification

Automatic handling and recording of defect anomalies

Automatic upload of defect data to the DN system and shipment system

Benefit and Effectiveness Example: Feedback from a 12-inch Semiconductor Front-End Customer

After the successful deployment of LOFA, OM machines can automatically identify and evaluate wafer defects, supporting remote monitoring and control. The intuitive operating interface allows managers to easily monitor production status and perform corresponding operations in real-time from anywhere. After LOFA's deployment, the number of MA personnel was reduced, further enhancing production efficiency and cost-effectiveness.

Glorysoft's successful application of LOFA in OM scenarios in 12-inch fabs represents a significant exploration in smart production and AI automation in dark factories this year. The multiple deployed cases also fully demonstrate Glorysoft's leading position and rapid integration of technology and cutting-edge science in semiconductor manufacturing automation. Responding to the urgent needs of the industry, we have also introduced applications for other machines besides OM and WAT, such as CP, CD-SEM, Review-SEM, and Die Saw, which will gradually be promoted to more application scenarios in the future. Glorysoft will continue to drive the intelligentization and unmanned process in the semiconductor manufacturing industry, providing more efficient and reliable solutions and technical support to global customers in advanced manufacturing.